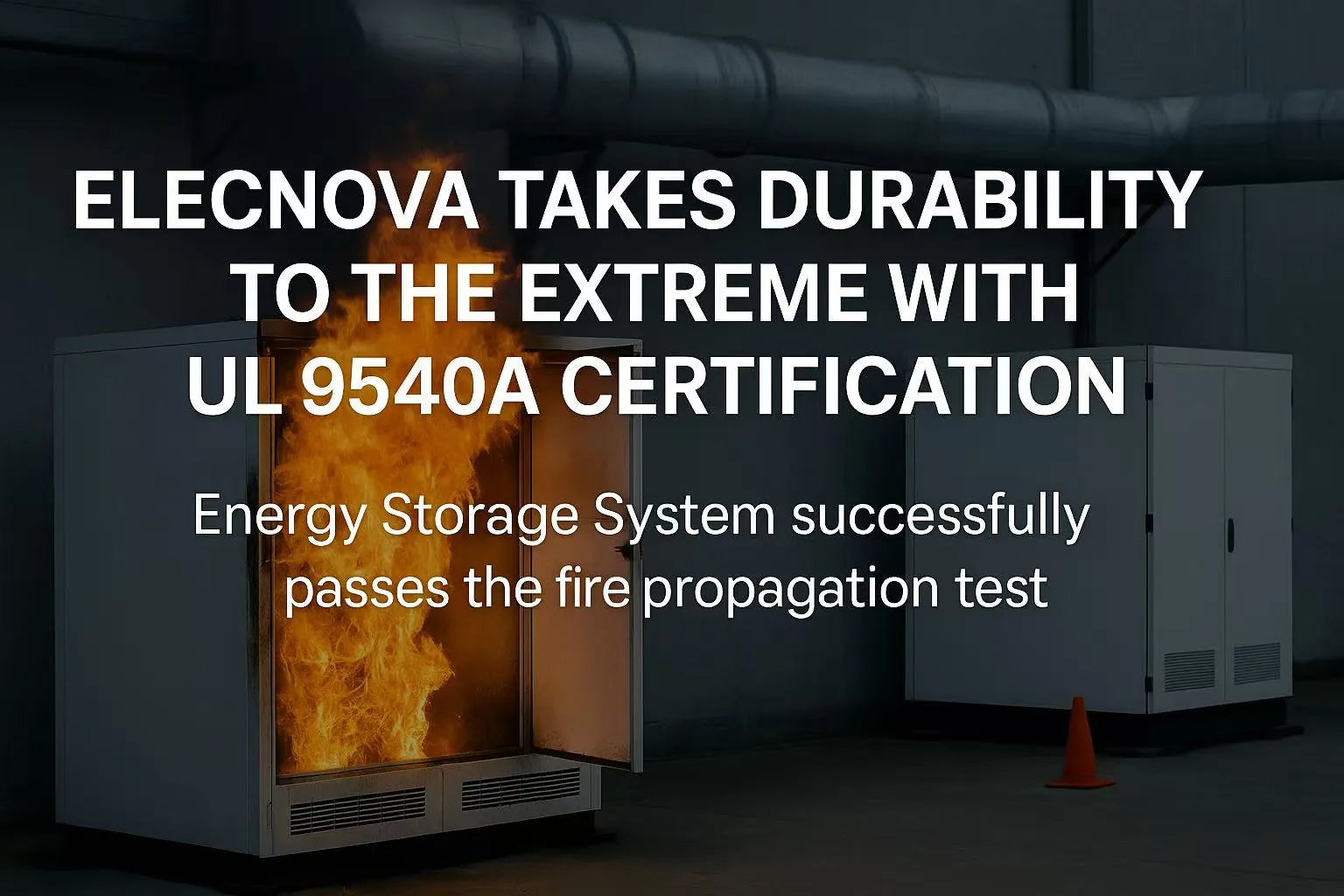

Elecnova’s Energy Storage System Successfully Passes UL9540A Thermal Propagation Testing at Both Module and Cabinet Level

Jul 08, 2025

Abstract

With the rapid global deployment of Battery Energy Storage Systems (BESS), fire safety and thermal propagation prevention have become critical parameters for technical validation and project bankability. This article presents the successful UL9540A certification of Elecnova’s C&I energy storage system, encompassing both cell/module-level thermal runaway containment and cabinet-level fire propagation mitigation. The results demonstrate that Elecnova’s system architecture meets and exceeds the required standards for fire safety performance in grid-connected and behind-the-meter applications.

Figure 1. Fire propagation test on ESS cabinet.

1. Introduction

As energy storage systems scale in capacity and application scope, their safety under extreme fault conditions—specifically thermal runaway events—has attracted increasing regulatory and commercial scrutiny. The UL9540A test method, developed by Underwriters Laboratories (UL), is widely recognized as the global benchmark for assessing thermal propagation risks in BESS.

UL9540A testing evaluates the ability of a system to:

- Contain thermal runaway events at the cell and module level;

- Prevent thermal propagation to adjacent modules or cabinets;

- Limit smoke and heat release within critical safety thresholds;

- Maintain structural integrity for safe emergency response and fire mitigation.

Elecnova conducted UL9540A testing with internationally accredited third-party laboratories under controlled ignition scenarios to validate product safety in real-world applications.

2. Testing Scope and Methodology

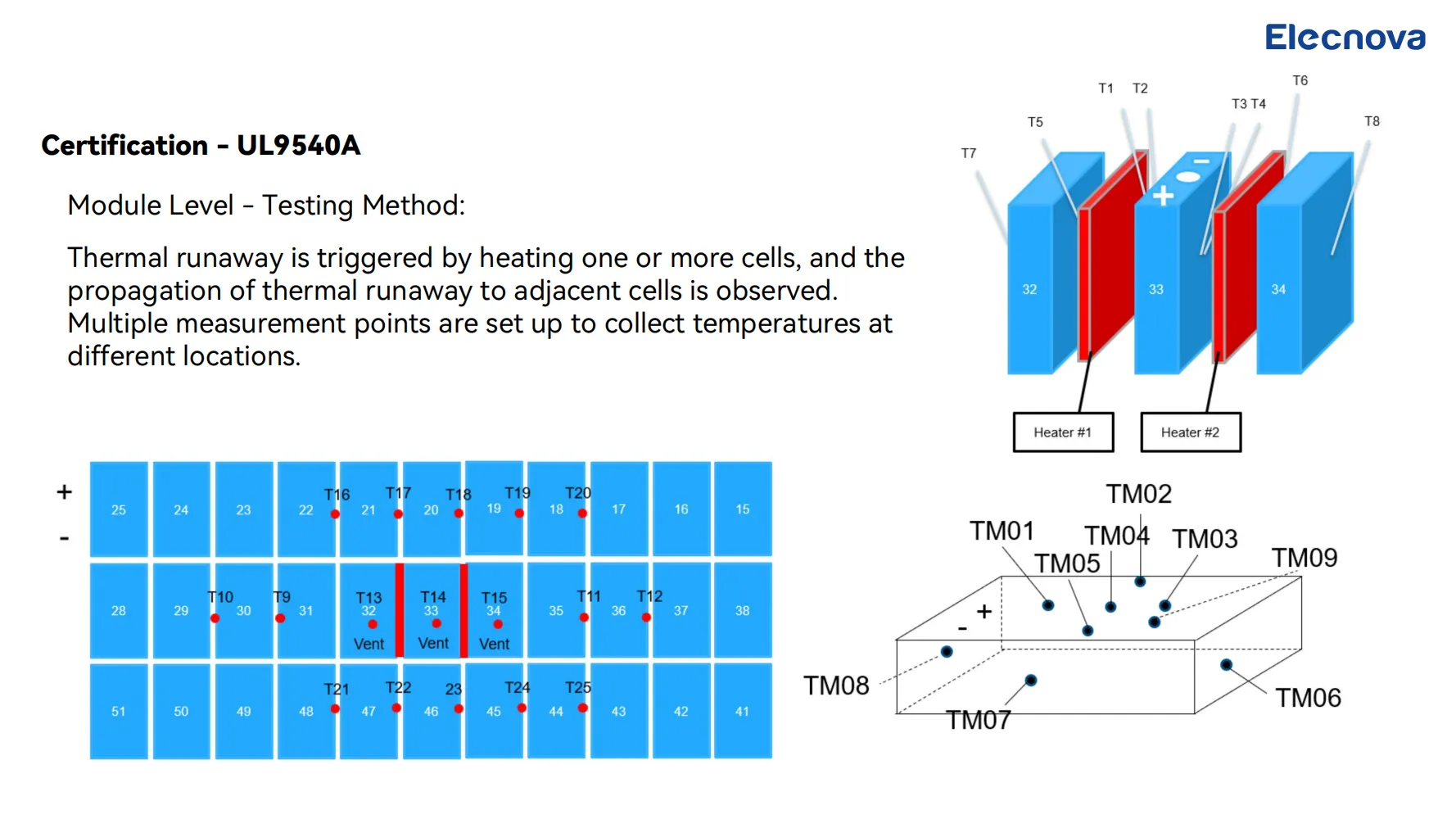

2.1 Module-Level Test

The objective was to trigger thermal runaway in one or more lithium-ion cells within a module and observe whether the event propagates to adjacent cells. Smoke release rate (SRR), heat release rate (HRR), and flame presence were monitored to assess containment performance.

Figure 2. Module-level UL9540A test schematic.

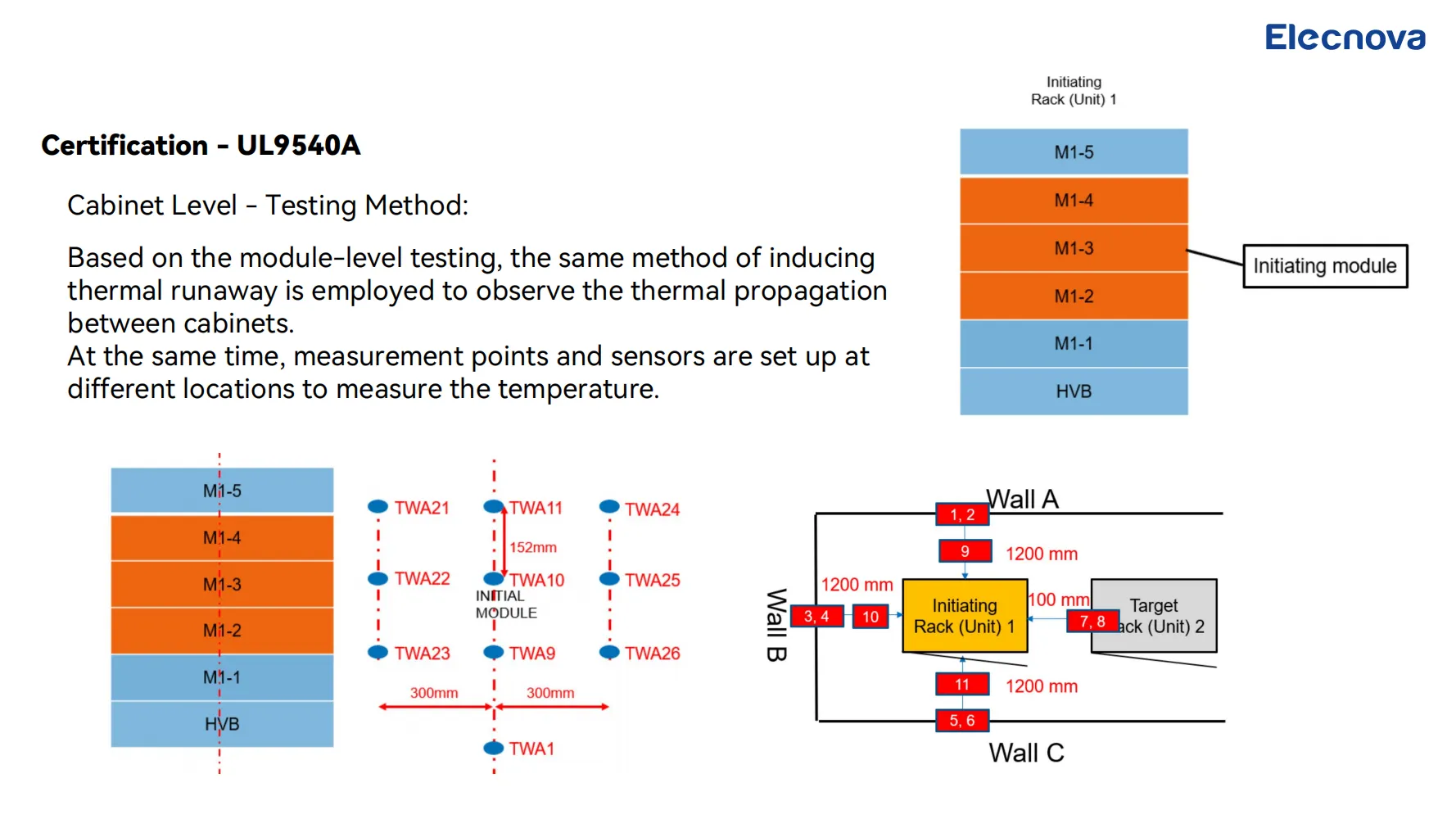

2.2 Cabinet-Level Test

A full storage cabinet was subjected to intentional thermal ignition. Temperature sensors were deployed around and within adjacent cabinets at close spacing to measure potential propagation under high-stress conditions.

Figure 3. Cabinet-level UL9540A test layout.

3. Results Summary

The Elecnova system passed all UL9540A requirements with the following key findings:

Parameter Result

Thermal propagation between cells Not observed

Cabinet-to-cabinet flame propagation None detected at 100mm separation

Smoke release rate (SRR) Controlled within acceptable thresholds

Heat release rate (HRR) No flaming observed

Structural integrity Maintained throughout ignition event

3.1 Extended Fire Resistance Observed During Testing

While UL9540A certification focuses on assessing thermal runaway and fire propagation risks in BESS, Elecnova’s system demonstrated outstanding safety performance. During full-scale testing, even after intentional initiation of thermal runaway in a single cell, no propagation occurred to adjacent cells or battery packs. The cabinet remained structurally intact, and no secondary ignition was observed—thanks to the high reliability of our battery cells, in-pack fire suppression system, and robust thermal isolation design. This result underscores Elecnova’s commitment to safety at both the cell and system level.

4. Technical Implications for System Design

The test results validate Elecnova’s multi-layered approach to thermal risk mitigation:

- Cell-level isolation to minimize chain reaction probability;

- Fire-segregated module enclosures for localized event containment;

- Compartmentalized cabinet design to reduce propagation vectors;

- Integrated pressure relief and ventilation structures to dissipate combustion gases safely;

- Optional aerosol or water-based suppression systems for enhanced response control.

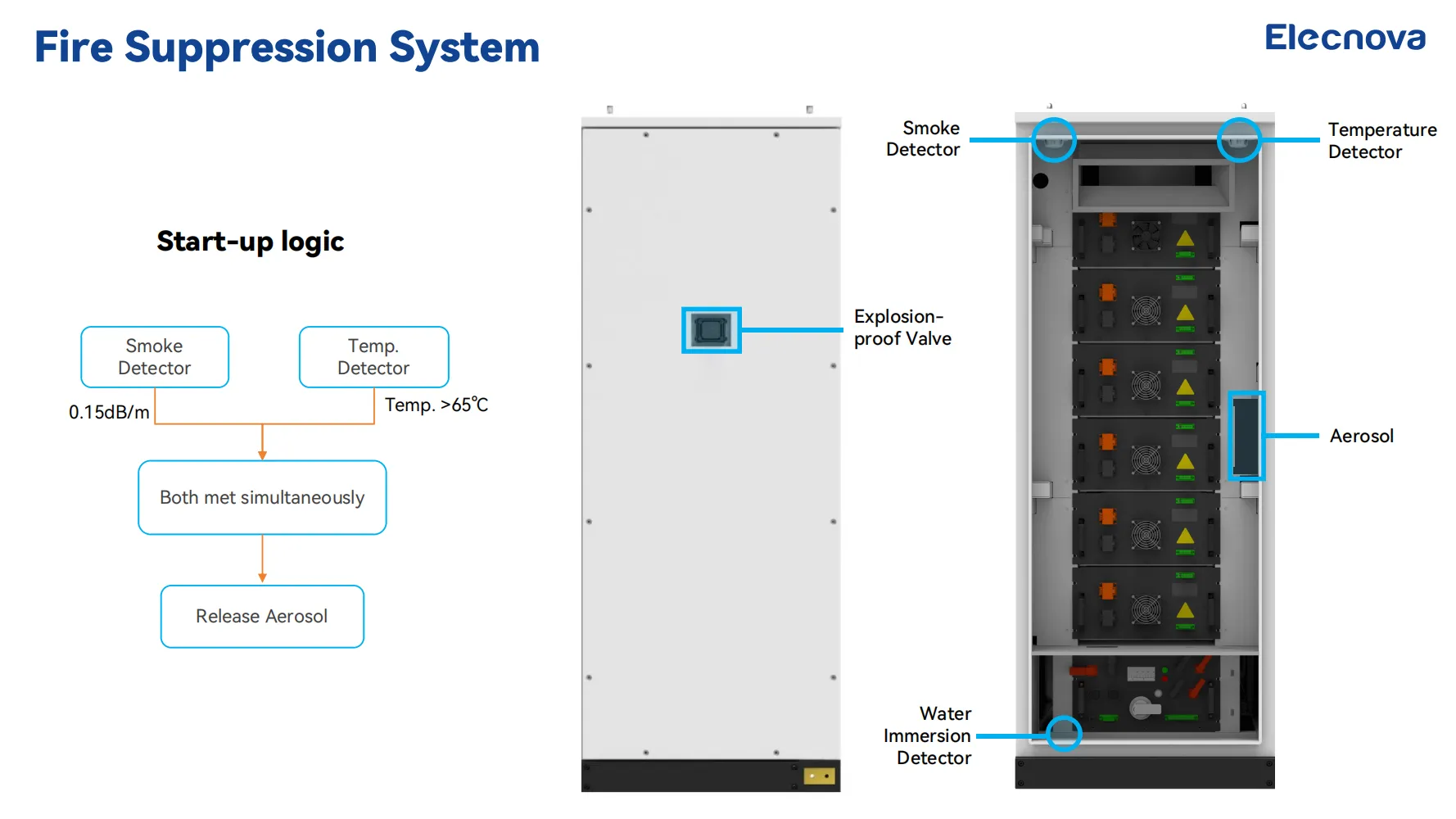

4.1 Integrated Fire Suppression System

Beyond structural containment, Elecnova’s BESS is equipped with an intelligent, integrated fire suppression system. This system adopts a dual-trigger start-up logic—requiring simultaneous detection of elevated temperature (≥65°C) and smoke concentration (≥0.15 dB/m)—before activating an onboard aerosol fire suppressant. The architecture includes explosion-proof valves, water immersion detectors, and embedded temperature and smoke sensors for autonomous and early-stage hazard mitigation.

This multi-layered design ensures fire response within milliseconds, offering superior cabinet-level risk control. The entire suppression system is housed within the cabinet itself and functions without external command or utility power.

Figure 4. Elecnova’s integrated aerosol-based fire suppression system.

5. Relevance to C&I Storage Applications

UL9540A certification strengthens Elecnova’s competitiveness in global C&I markets where:

- Regulatory compliance is mandatory for project permitting;

- Insurance providers require third-party safety validation;

- EPCs demand system robustness to reduce liability and improve uptime;

- End-users seek operational assurance for rooftop, factory, and grid-connected installations.

6. Conclusion

The successful UL9540A module and cabinet-level certification of Elecnova’s BESS demonstrates the system’s ability to withstand and contain thermal incidents without flame propagation or structural compromise. This milestone reaffirms Elecnova’s engineering focus on safety-driven design and reinforces its commitment to delivering secure, reliable, and regulation-compliant energy storage solutions for critical commercial and industrial energy infrastructure.

CONTACT US

As a scientific and technological innovation enterprise,Shanghai Elecnova Energy Storage Co., Ltd. specializes in ESS integration and support capabilities including PACK, PCS, BMS and EMS.

- Address :

3F-T1.Hongqiaohui,Shanghai,China

- Phone : (+86-510) 86199028

- Email : sales@elecnova-ess.com

- Whatsapp : +86 19906165606